Infusion Process

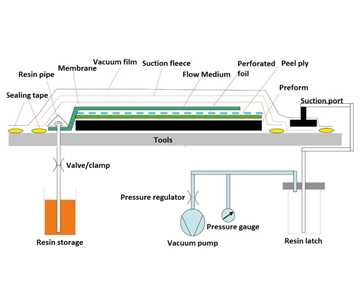

The Vacuum Assisted Resin Infusion Molding Process (VARIM) is a technique that uses vacuum pressure to drive resin into a laminate.

INFUSION PROCESS

PROCESS

- The Vacuum Infusion Process (VIP) is a technique that uses vacuum pressure to drive resin into a laminate.

- Materials are laid dry into the mold and the vacuum is applied before resin is introduced. Once a complete vacuum is achieved, resin is literally sucked into the laminate via carefully placed tubing.

- This process is aided by an assortment of supplies and materials.

- An improvement on that method is to use a vacuum bag to suck excess resin out of the laminate.

- Vacuum bagging greatly improves the fiber-to-resin ratio, and results in a stronger and lighter product.

Why use the infusion process?

The resin infusion process is a cost effective method of manufacturing high quality and high strength composite parts that are required in relatively low quantities, say less than a few hundred identical pieces per mould per year, or physically large parts which are difficult, or prohibitively expensive to make by any other method.

BENEFITS

- Better fibre to Resin ratio

- Stronger laminate

- Low void content

- Reduces operator exposure to harmful emissions

- Reduced resin usage due to pre-compacted fabric

- Faster Ply lay-up

- Cleaner Process

- Highly even quality and laminate thickness

- Better for sandwich constructions