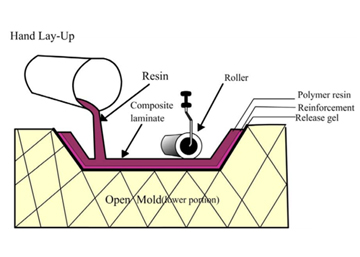

Hand Lay Up Moulding

Fiber Reinforced plastics are the polymer matrix composites made up of unsaturated polyester resin with glass fiber reinforcement.

HAND LAY UP MOULDING

MATERIALS USED

Matrix Epoxy, polyester, polyvinyl ester, phenolic resin, unsaturated polyester, polyurethane resin Reinforcement Glass fiber, carbon fiber, aramid fiber, natural plant fibers (sisal, banana, nettle, hemp, flax etc.) (all these fibers are in the form of unidirectional mat , bidirectional (woven) mat, stitched into a fabric form, mat of randomly oriented fibers)

HAND LAY-UP METHOD

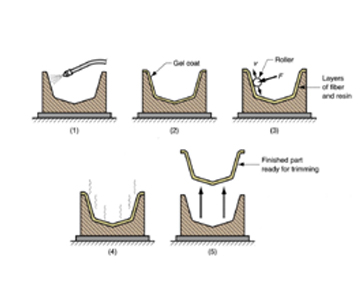

Open mold shaping method in which successive layers of resin and reinforcement are manually applied to an open mold to build the laminated FRP composite structure

- Labor – intensive

- Finished molding must usually be trimmed with a power saw to size outside edges

- Oldest open mold method for FRP laminates , dating to the 1940 when it was first used for boat hulls

HAND LAY-UP

Hand lay - up, or contact molding, is the oldest and simplest way of making fiberglass-resin composites, Applications are standard wind turbine blades, boats, etc.

BENEFITS

- Flexibility in reinforcing materials

- Can produce a very strong part

- Improved thickness variations over other low volume processes

LIMITATIONS

- Can produce a very strong part

- Improved thickness variations over other low volume processes